In our Meet The Distiller editorial series we chat with Scotland’s growing number of talented distillers to learn more about their own journey into the world of Scottish Gin and spirits. The number of distillers and how they came to find themselves involved is distilling is varied and diverse. Some graduated from the Institute of Brewing & Distilling at Heriot Watt University in Edinburgh, others are self taught. One thing they all share is a determination and passion to make brilliant Scottish Gin and spirits.

In this feature we meet Iain Robertson, Head Distiller at the Isle of Raasay Distillery. Originally opened in 2017, the Isle of Raasay Distillery was the first legal distillery on the island and produces a variety of Scottish spirits including whisky and Isle of Raasay Hebridean Gin, which was launched in 2019. The island itself is only a short ten minute boat ride from the Isle of Skye and sees you crossing a stretch of water known as the Sound of Raasay with a trip that provides stunning vistas of the local area. With distillery tours, private events and more, the distillery has been a hub of activity for the last two years and saw the second onsite warehouse for storage completed in late 2019.

What’s your name and what do you do?

I’m Iain Robertson. Head Distiller at the Isle of Raasay Distillery.

What’s your background?

I studied Brewing and Distilling at Heriot Watt University and worked at the Scotch Whisky Experience in Edinburgh throughout my degree as a tour guide and tasting team member. I also did a placement at the North British Distillery.

What spirits are you involved in making?

We make peated and unpeated single malt whisky on the Isle of Raasay as well as our Isle of Raasay Gin. We released our gin earlier this year, and in 2020, we will release our inaugural Isle of Raasay Single Malt, which is very exciting.

What kind of research goes into making a new product?

A lot of research goes into making a new product, a lot more than I was aware of. For our gin, thankfully we had a great project manager who looked into everything from design of the bottle to our target market. For the liquid, the bit I was involved in, we did a lot of desk and field (literally) research into Raasay’s native botanicals, with the help of a local botanist. Then we worked with a Heriot Watt University MsC student who took our chosen botanicals and distilled them individually on small glass stills so we could decide which ones we liked best, and at which quantities. We sampled single distilled botanicals on their own and blended together, and subsequently we tried our preferred botanicals distilled together to see how they interacted with one another to achieve the desired flavours. We ruled out a few botanicals through that process and decided how much or how little of the others we wanted in our gin, before scaling up and finding the quantities that worked on our stills in Raasay. There was a fair amount of gin tasting involved in our research!

Do you get the opportunity to experiment?

For the gin, not so much yet. We wanted to make sure we were really happy with the core gin before I start playing around with botanicals and changing it too much. But in the future, there might be a few experimental batches, you never know.

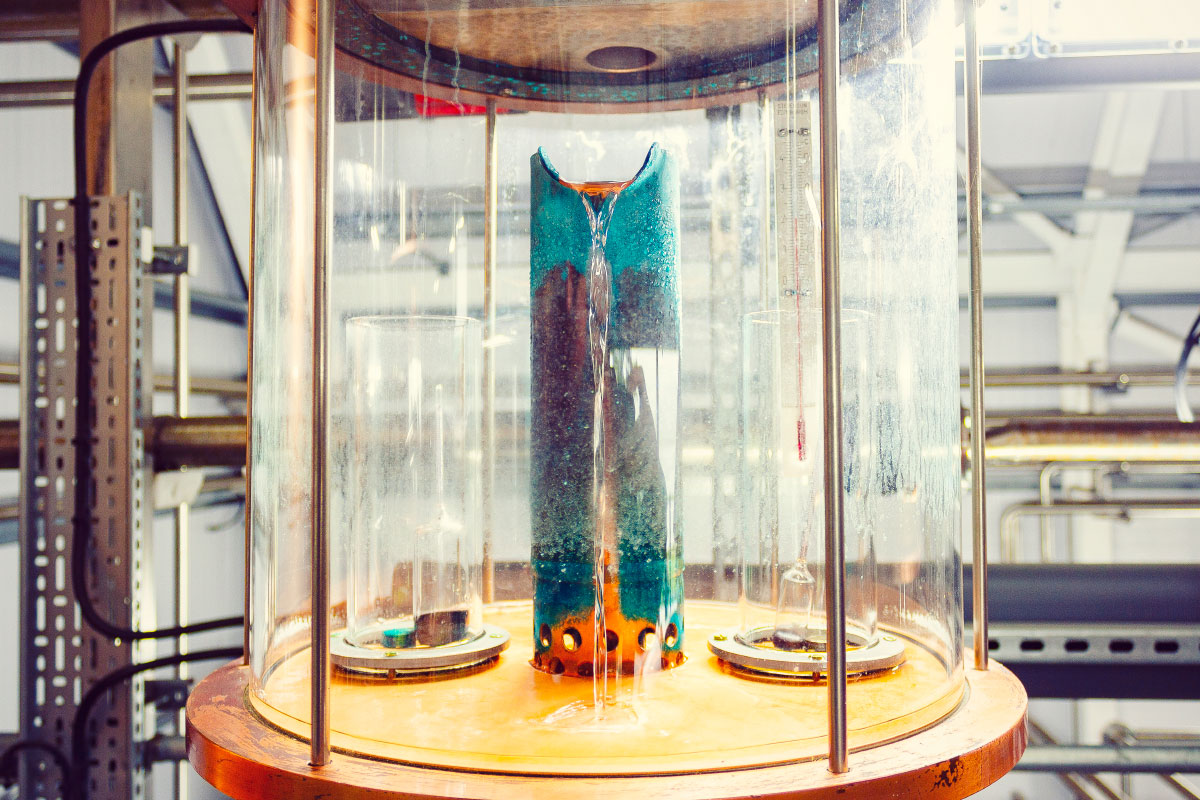

For our whisky, we experiment a lot with our equipment. It’s difficult to explain without actually seeing our stills, but they have a few variations that allow us to create different spirits depending on what we are looking for. For example, our first release whisky combines two different types of our Raasay spirit – peated and unpeated. Our wash made from peated barley is distilled using our uniquely designed cooling jacket on our lyne arm so that some of the spirit vapour condenses early and returns to the wash still. This extra loop allows us to build up some of the heavier characteristics we want in our peated spirit. When we run our unpeated wash, the cooling jacket is turned off to help create a balance of heavier and lighter flavour compounds in our final spirit. We also use different yeast strains, fermentation temperatures and oak varieties, and we have been running trials growing our own barley on Raasay.

What’s your no. 1 rule when making spirits?

With everything we make, we prioritise provenance and consistency. I make sure that our operators record everything they do, so if there are any changes in our spirit, we can work out why. With the gin, even a change in flow from the stills might be an indication of something changing.

What’s the best part of the gin making process?

I love putting all the botanics in the basket and the stills. You get to smell the aromas and get a sense of what is to come.

What’s the worst part of the gin making process?

There are a few stages of the process that aren’t what you’d call fun, but nothing too drastic. If I was to pick one, I’d say putting the seal strips on top of the gin bottles. The amount of times I have put it on squint… it’s a job for someone with more grace than me! I know it looks good on the bottle, but it’s a task I delegate to someone else quite often.

What’s your ultimate drink?

I don’t know if I have an ultimate drink or not. I mean, I am a whisky drinker, so I’ll say whisky. But I’ve recently started to explore the world of red wines. And after all that research drinking different gins, I’m also partial to a G&T.

Tell us something we might not know about Isle of Raasay Distillery.

We are really lucky to have an onsite distillery well, which we discovered was traditionally called Tobar na Ba Bàine, meaning the Well of the Pale Cow. Our gin is 46% ABV, which means 54% of it is Raasay water, so our water source is really important. Our water flows over hard, impervious volcanic rock, which is abundant on Raasay, and gathers under the hills behind the distillery. We then draw it up through 60 metres of rock, including porous sandstone, which makes up much of our site. The result is a mineral-rich water for our Raasay spirit. When we make our whisky, long fermentations, combined with manganese from our well water, which is ideal for yeast development, helps achieve sweet and dark fruit characteristics in our spirit before it even touches the cask. All water we use in production, diluting and tasting is from the same single source at the distillery and we have a filtration system with a UV filter that can make it into drinking water. A lot of geology students come up to Raasay to study the island’s unique geology, and the geological strata were even used as part of the inspiration for the Isle of Raasay Gin bottle design. There is a long history of illicit distilling on Raasay, so it’s quite cool to imagine what the gins of years gone by tasted like using that same water, and likely the same Raasay juniper!

You can learn more about Isle of Raasay Distillery here.

You can learn more about Isle of Raasay Distillery by visiting the links below.